Equipment manufacturing divison

- Manufacturing of components and devices for the associated divisions and for the civil customers

- Monitoring of the manufactured components by a 3D measuring machine

- Manufacturing and marketing of Hospital technology equipment

Short review of the technological capabilities

Metal cutting

- Cutting

- Bandsaw machines – cutting size max: 280 mm caliber

- Plasma cutting (manual)– cutting size for steel max: 15 mm

- Flame cutting (manual)– cutting size for steel max: 50 mm

- Turning

- Traditional lathe – tipical size: 500mm – 2500 mm

- CNC lathe – tipical size: 180mm – 1000 mm

- Milling

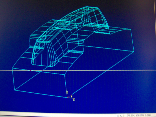

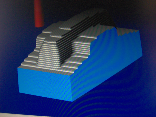

- 3D CNC milling machine – size: 400 x 450 x 600 mm

- 4D CNC boring mill – size: 1000 x 1000 mm

- Traditional milling machine – size: 450 x 1000 mm

- CNC engraving

- Drilling

- Columnar and stream drilling machines for maximum 60 mm hole caliber

- Coordinate drilling machine with 0.001 mm precision – size: 350 x 400 mm

- Grinding

- Surface grinding – size: 350 x 800 mm

- Plain grinding – size: 200 x 750 mm caliber

- Internal grinding – size: 100 x 250 mm caliber

Metal (plate) cold working

- Cutting on hydraulic plate shears, steel: max 3 x 2000 mm

- Edge bending on hydraulic edge bending machine, steel: max 3 x 1700 mm

- Cutting, puncturing, deep drawing: max 50 t deformation force

- Rolling, steel: max 3 x 2000 mm

Welding

- Welding of steel, aluminium, stainless steel, etc

- With certificated ISO 2 and 3 welders

- With independent welding specialist

- Manual torch welding, and sealing (with copper, silver, etc.)

- Manual arc welding, with specific electrodes too

- Manual gas-shielded arc welding

- CO2 gas-shielded, consumable electrodes (ESAB machines)

- Argon gas-shielded, tungsten electrodes (Kempi, Velding machines)

- Manufacturing of components

- Reparing devices, parts, fittings and machines

- Manufacturing of casings and electrical switchboards

- Manufacturing precision mechanical works

- Manufactureing tools, gears and models

- Curing of unique, small-scale rubber and bakelite components

- Preperation of shop drawings based on samples

- Preperation of 3D machining programs based on shop drawings